Product advantages

Technical-parameters

Core advantages

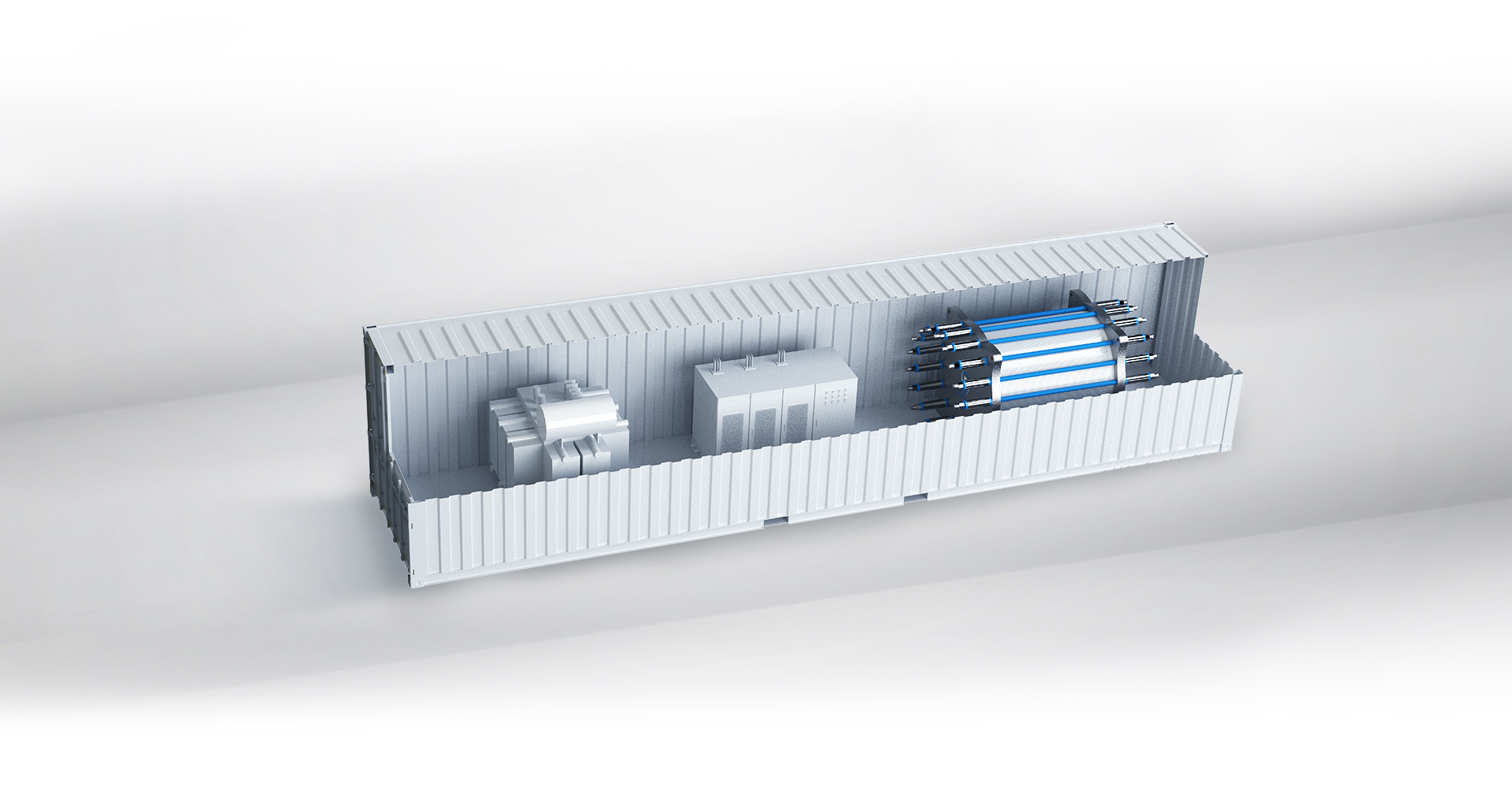

The hydrogen electrolyzed by the electrolytic cell contains more lye. First, the lye is separated by the gas-liquid separator, and then the residual lye is further separated by the scrubber to obtain pure hydrogen.

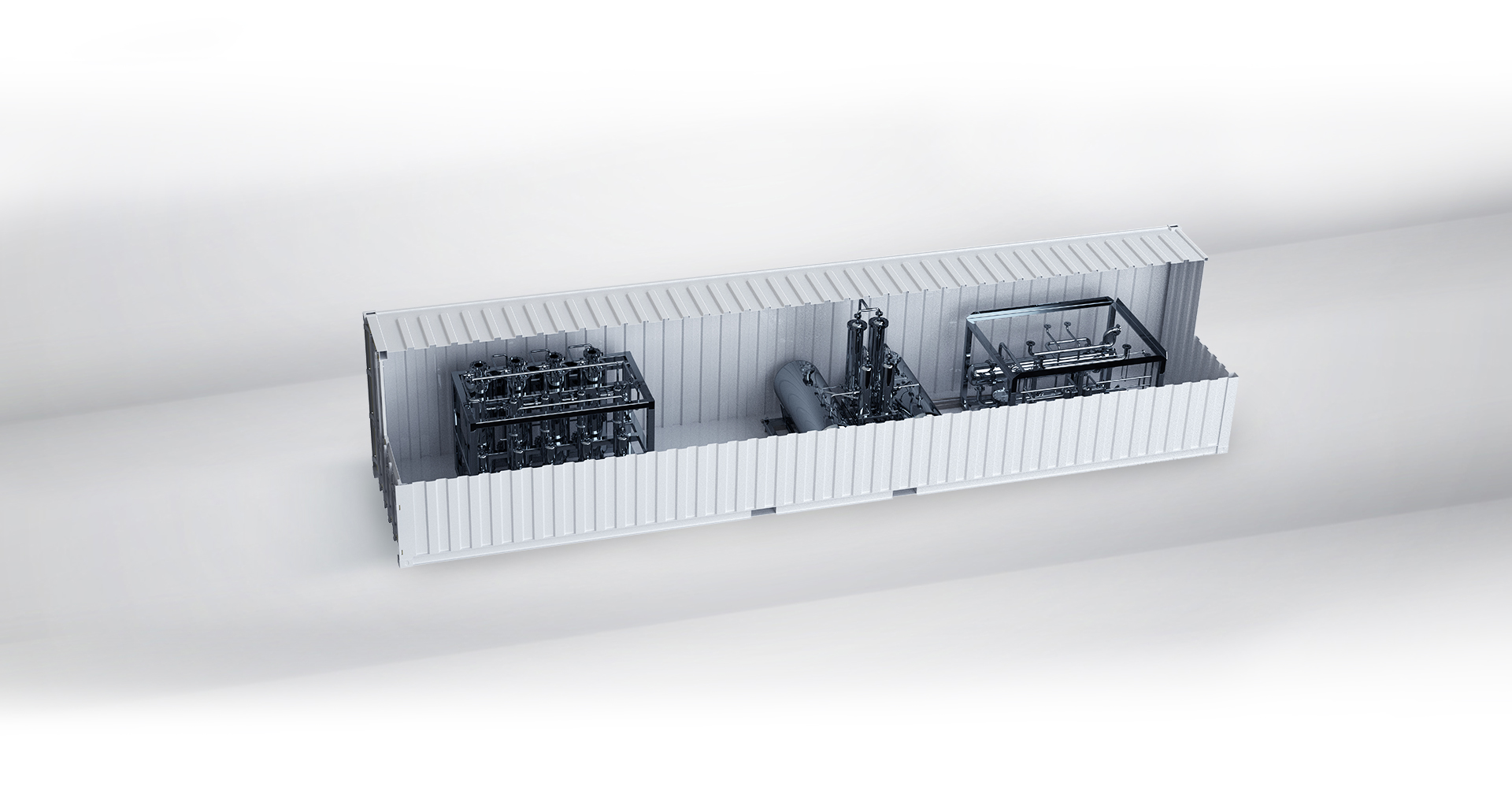

Modular design

The product adopts modular design and standardized delivery. It is convenient for transportation, suitable for large-scale solutions, and can be arranged nearby according to hydrogen demand.

Two-stage efficient gas-liquid separation

Gravity sedimentation separation is used to sink the liquid in the gas-liquid mixture entering the separator to the bottom of the separator. The gas part enters the cooling water pipe in the upper space of the separator to maintain a low temperature in the separator. The temperature drop makes the atomized liquid particles in the gas form large droplets, and the large droplets fall into the liquid below due to their weight to realize gas-liquid separation.

100/500/1000

Nm³/h

Hydrogen yield

0.25/0.5/2.5

W

Product power

4.0/4.2/4.4

kWh/Nm³

DC power consumption

Specification

and model |

Container type hydrogen

production equipmen 100 |

Container type hydrogen

production equipmen 500 |

Container type hydrogen

production equipmen 1000 |

| standard container(set) |

2(20inch) |

4(40inch) |

4(40inch) |

|

hydrogen production(Nm³/h)

|

100 |

500 |

500 |

| oxygen production(Nm³/h) |

50 |

250 |

1000 |

| Operating pressure(Mpa) |

1.6-2.0 |

| DC power consumption(kWh/Nm³) |

4.0/4.2/4.4 |

| Rated power(%) |

30-120% |

| Load range(℃) |

90±2 |

| Electrolyte(KOH solution) |

30% |